It's Getting Hot at SSC

Hot Hydrogen Heat Source Development

PM: David Coote |

Fiscal Year: 2014 |

Status: Completed |

This study was part of a broader assessment of ground testing facility technology development

at Stennis Space Center for testing non-nuclear thermal propulsionsub-scale

systems. One specific technology need was the ability to provide high temperature hydrogen,

above the auto ignition temperature of 1390 R, at a flow rate as high as 2.2 lb/sec and for a

duration of five minutes. Assessment of five concepts was performed and included: the High Heat

Flux Rig, the Hydrogen Wave Heater, the VTX HyHeat combustion chamber, fuel-air burners, and an

electric resistance heater. Of the five concepts assessed, the more conventional Fuel-Air Burner

was identified as the best near-term solution for testing at the E-Complex at SSC. With the exception

of the Electric-Resistance Heater concept, all concepts were also identified as feasible, some with

stipulations.

The high heat flux test rig is capable of combusting between 1.3 and 15 lbm/sec of hydrogen and 5.2

and 59 lbm/sec of oxygen, providing a recovery temperature between 4500 R and 6000 R.

CFD Evaluation of NTP Test Options

Development of CFD Approaches for Modeling Advanced Concepts of NTP Test Facilities

PM: Danny Allgood |

Fiscal Year: 2014 |

Status: Completed |

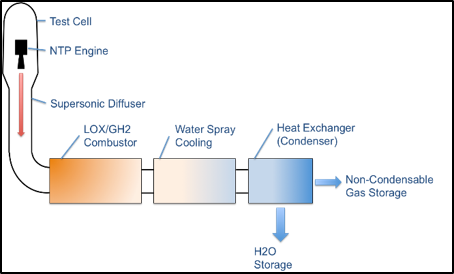

The development of a nuclear thermal propulsion (NTP) engine for manned spaceflight missions

to Mars and other distant exploration sites will require a ground test facility that is capable

of test firing the engine safely and with zero harmful emissions. This project examined several

design concepts for such a NTP ground test facility. These include, but were not limited to,

borehole, scrubber and total-containment systems.

Nuclear thermal propulsion total containment test facility concept

Data Acquisition and Control Systems Demo

Novel Data Acquisition and Controls Systems Demonstration

PM: Nick Nugent |

Fiscal Year: 2014 |

Status: Completed |

The project built, installed, and tested a novel data acquisition and control system

by combining two independent architectures into one standalone unit. The simplified

architecture reduces component numbers while maintaining the strict hardware reliability

demands and high mean time between failures. Implementation of this technology potentially

reduces hardware and software costs as it relates to the operation of a control center.

This project demonstrated two immediate and significant benefits to NASA:

Development of a novel data acquisition and controls architecture that does not rely

on PLCs thus improving control loop rate speed.

Creation of a separate, stand alone, data acquisition and control system for use on

small scale projects that are independent of the test complex acquisition and control systems.

Novel data acquisition and control system

Oxygen Containment Systems Options

Oxygen Containment Systems Options

PM: Ke Nguyen |

Fiscal Year: 2014 |

Status: Completed |

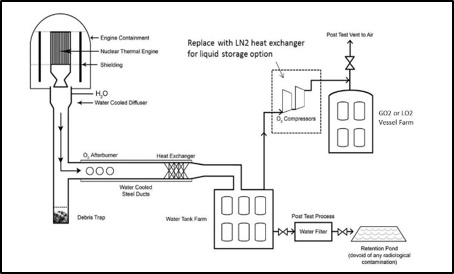

NTP engine exhaust, hot gaseous hydrogen is nominally expected to be free of radioactive

byproducts from the nuclear reactor; however it has the potential to be contaminated due

to off-nominal engine reactor performance and therefore prevents its free venting to the

atmosphere. This project evaluated two options for gaseous O2 retention: (1) compression

and (2) liquefaction. After comparison studies were performed it was determined the liquid

storage option is recommended based on storage tank volume, cost, risk and safety considerations.

The liquid storage option has no mechanical moving parts and operates at low pressure compared

to the gas storage.

NTP exhaust containment system

Subscale Design of a NTP Engine Exhaust

Subscale Design of a NTP Engine Exhaust

PM: Jody Woods |

Fiscal Year: 2014 |

Status: Completed |

Nuclear Thermal Propulsion is an option for NASA to extend humanities

reach to destinations such as Mars. The goal of this project was to develop preliminary

design elements and integrated systems for making a proof-of-concept technology demonstrator

subscale system for a non-nuclear rocket engine. The results of this project identified a

design concept for a non-nuclear subscale demonstrator at SSC's E3 test stand. In addition

the project determined the physical arrangements required at E3 while refining the cost and

schedule estimates for design, build and execution of a subscale technology demonstrator project.

Potential subscale test sight location