Additive Component Manufacturing

3D Printing for Better Valves

PM: Jonathan Dickey |

Fiscal Year: 2019 |

Status: Active |

Current technology relies heavily on centuries-old techniques like casting, forging, and

machining to create fluid control valves, significantly limiting what can be manufactured.

State of the art technologies, such as additive manufacturing, have not yet been thoroughly

applied to fluid control valves. Many valve manufacturing issues, such as flow passage

machining, deep hole boring, and bi-metallic joining, could successfully be addressed using

additive manufacturing technologies. The goal of this project is to apply additive manufacturing

techniques specifically to the problems fluid control valves present.

Rocket engine 3D printed at Marshall Space Flight Center

Autonomy Strategies: Ontology and Implementation

Developing and Implementing Autonomy Strategies to Enable “Thinking Autonomy”

PM: Fernando Figueroa |

Fiscal Year: 2019 |

Status: Active |

Autonomy strategies enable systems to overcome unplanned events that affect the

nominal execution of a mission. This project will address a crucial gap in the

development and implementation of autonomy strategies to enable “Thinking Autonomy.”

Experts from SSC and JPL will collaborate to develop a substantive list of autonomy

strategies founded on experience. With this data, a taxonomy, architecture, and

language for autonomy strategies will be developed and properly documented. The first

phase of the project will focus on efforts to conceptualize and formulate an ontology

for autonomy strategies at high levels of abstraction and generate some initial language

modules for a space habitat (e.g. power, ECLSS) and the SSC nitrogen storage and distribution

system. In parallel, we will begin implementation of the capability in SSC’s NASA Platform for

Autonomous Systems (NPAS) and carry out verifications.

Logo for the NASA Platform for Autonomous Systems

Hydrocarbon Cold-Flow Simulation of LOX/LH2 Rocket Aerodynamics

Mimicking Rocket Plume Aerodynamics with Natural Gas Byproducts

PM: Daniel Jones |

Fiscal Year: 2019 |

Status: Active |

Current analytical and empirical rocket diffuser design methodologies

are inhibited by the limited envelope of available experimental data

collected via low-pressure nitrogen and steam testing in the 1960s.

The goal of this project is to develop and demonstrate a lab-scale

hydrocarbon cold-flow simulation of coupled rocket/diffuser system

aerodynamics. The objectives for year one include design and fabrication

of a hydrocarbon cold-flow rocket/diffuser testbed and a test article

representative of a hot-fire system that has already been experimentally

characterized. Year two includes tasks to activate the test bed, perform

a series of cold-flow tests on one or more rocket/diffuser configurations,

and characterize the performance of the ethane simulation compared to hot-fire.

RS-25 being tested at NASA's John C. Stennis Space Center

Prediction of Safety Incidents

Enhanced Safety Using Machine Learning

PM: Kamili Shaw |

Fiscal Year: 2019 |

Status: Active |

Safety incidents, including injuries, property damage and mission failures,

cost NASA and contractors thousands of dollars in direct and indirect costs.

Current data systems are able to collect and store information on both hazards,

through inspections and employee identification programs, and incidents. However,

NASA has not connected these sets of data to be able to predict safety incidents

and ultimately direct limited resources to the most high risk areas. This project

seeks to define, develop and test an algorithm that will use hazard identification

data as input to predict when and where there is a high probability of a safety

incident occurring. The ultimate goal is to take advantage of advances in the areas

of machine learning, data analytics and big data to save time, money and lives.

Dashboard Image of the SSC’s SMA Crystal Ball

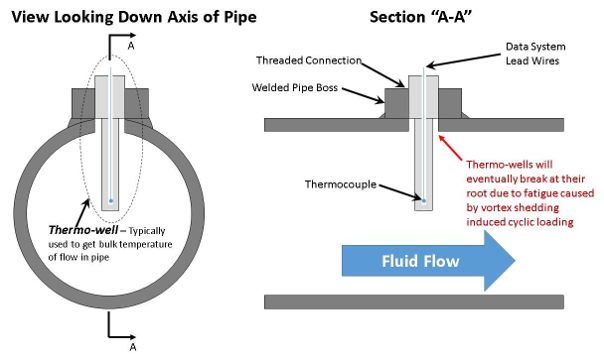

Multi-Physics Based Thermo-Well Fatigue Design Tool

Reducing the Potential for Fatigue Induced Mechanical Failures

PM: Jody Woods |

Fiscal Year: 2019 |

Status: Active |

Currently the thermo-well design method in use at Stennis Space Center (SSC)

is an outdated method that is known to be too conservative and sometimes

results in a required thermo-well size that adversely affects other design

parameters. This project will focus on the development of an innovative

thermo-well design tool based on a multi-physics software package currently

being developed by Mississippi State University (MSU) called the CalculiX

Structural Solver. The project will develop a multi-physics based thermo-well

fatigue design tool, then conduct verification and experimental validation

studies using it, and finally deliver a production ready tool for SSC’s use.

Cross section of a pipe highlighting the thermocouple