Stennis Space Center (SSC) tests liquid rocket engines and

components for NASA, the Department of Defense and the

commercial space industry. Rockets, and the facilities used

to test them, are precision systems that experience extreme

temperatures, high vibrations and high pressures during

operation. During ground testing, accidental propellant

detonation, such as the one in Figure 1, can generate strong

pressure waves. The ability to predict these blast occurrences

enables SSC to reduce risks to test facilities and adjacent test articles.

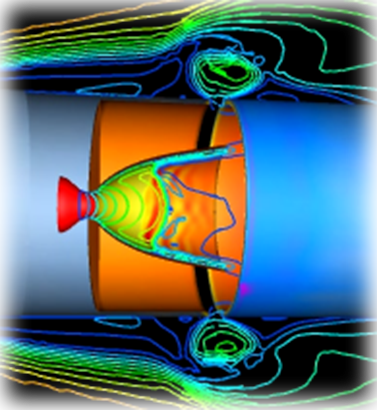

Rockets generate thrust through rapid chemical reactions. Modeling

and simulating these reactions requires specialized software, such as

Loci/CHEM, developed by Mississippi State University. Loci is a

rule-based framework that efficiently maps numerical algorithms

to parallel processing systems. CHEM is a Navier-Stokes solver

for non-equilibrium flows involving chemical reactions. Loci/CHEM

can simulate the complex 3D flows of turbulent, chemically reacting

mixtures found in rocket engines.

SSC engineers utilized Loci/CHEM to develop a practical, high fidelity,

computational fluid dynamics (CFD) methodology to predict the occurrence

of detonation events during liquid rocket engine tests, and to understand

the propagation of blast waves through test facilities. Verification and

validation studies were completed for hydrogen-fueled detonation phenomena,

such as shock-induced combustion, confined detonation waves, vapor cloud

explosions, and deflagration-to-detonation transition (DDT) processes.

The DDT validation cases included predicting flame acceleration mechanisms

associated with turbulent flame-jets and flow-obstacles. Excellent comparisons

between test data and model predictions were observed. This new capability

has been successfully applied to model a detonation that occurred during liquid

oxygen/gaseous hydrogen rocket diffuser testing at Stennis Space Center.