Metamaterial Energy Harvesting Demo

Deployable Thermoelectric Metamaterial Energy Harvesting Monitoring System

PM: Scott Jensen |

Fiscal Year: 2015 |

Status: Completed |

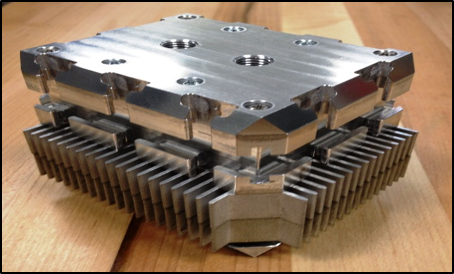

This project focused on taking a prototype energy harvester and making it available

for use within the harsh explosive environments throughout the Stennis Space Center's

ground propulsion test facilities.

Deployable thermoelectric metamaterial monitoring unit

Non-conventional Locomotion

Realizing Practical Nitinol Locomotion

PM: Scott Jensen |

Fiscal Year: 2015 |

Status: Completed |

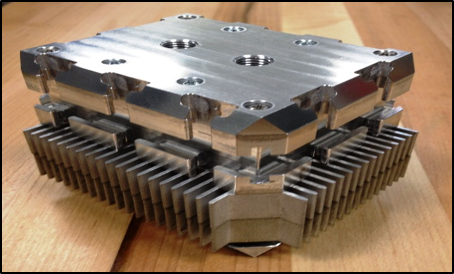

The purpose of this project was to construct a lightweight, power efficient, remote control,

miniaturized crawler for retrieving and shelving stored items by utilizing an advanced nitinol

wire locomotion device that incorporates a novel cooling mechanism. This kind of device has

practical applicability for accessing and transporting hardware components used throughout the

ground propulsion test facilities. Nitinol wires are unique nickel-titanium alloys that shorten

in length when heated, and can lift thousands of times their own weight with forces over 50 tons

per square inch.

Nitinol locomotion testing apparatus

Predicting the Boom from Rocket Engine Testing

Development & Validation of Propellant Detonation and Propagation Modeling

PM: Danny Allgood |

Fiscal Year: 2015 |

Status: Completed |

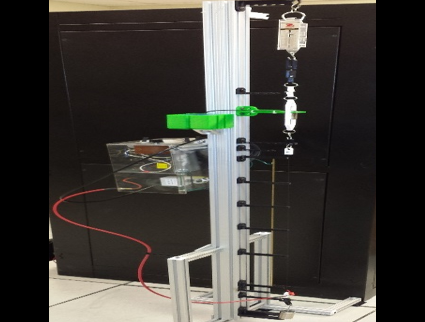

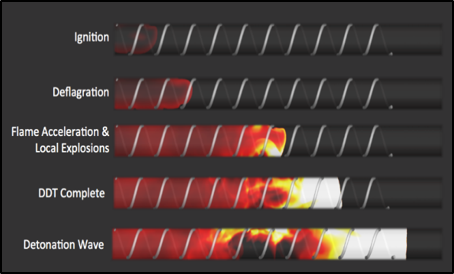

Testing of chemical rocket propulsion systems involves the potential for high-energy explosions

due to the delayed ignition of propellant flows. The ability to predict these blast environments

is critical to the safety of the test/launch facility. The technology developed and demonstrated

in this project provides a validated engineering tool and methodologies to be used by NASA centers

for predicting potential propellant detonation events during rocket testing or launch programs.

Furthermore, this project enabled a stronger foundational understanding of the necessary finite-rate

chemistry models to accurately predict high-speed deflagrations, deflagration-to-detonation transition,

as well as two-phase cryogenic propellant detonations.

3D deflagration-to-detonation-transition event caused by spiral geometry inside a pulse detonation engine during testing at SSC

Large Propellant Tank Cryo-Cooler Concept

Large Propellant Tank Cryo-Cooler Demonstration (LPTC)

PM: Jody Woods |

Fiscal Year: 2015 |

Status: Incomplete |

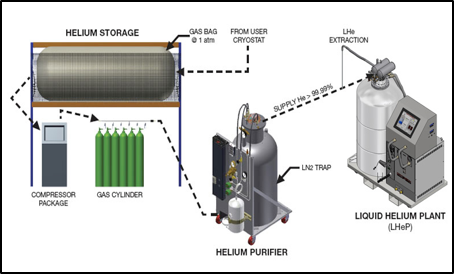

The focus of this project was to develop a design concept that utilizes off the grid electricity or solar energy

to power scalable commercially off-the-shelf cryogenic-cooler technology required for test and launch facility

cryo-storage tanks. The LPTC is a system that uses either electricity or solar energy to drive a heat engine

that continuously removes the heat that naturally leaks into a cryogenic propellant storage tank from its ambient

environment. If developed this technology would have saved money associated with the operation, maintenance and

ground operations of launch facilities.

Large propellant cryo-cooler concept

Monitoring the Health of Critical Systems

Gas House Autonomous System Monitoring

PM: Fernando Figueroa |

Fiscal Year: 2015 |

Status: Completed |

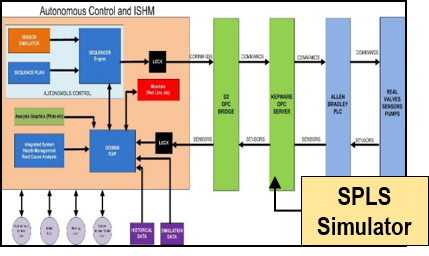

The objective of this project was to develop an autonomous monitoring system capable

of assessing the condition of every element in the system, continuously and

comprehensively. The Gas House Autonomous System Monitoring (GHASM) is an intelligent

knowledge based system drawing inferences and conclusions on the state of system elements

i.e., sensors, valves. GHASM will be integrated across systems and subsystems to implement

functional capabilities of an Integrated System Health Management. These capabilities

include (1) anomaly detection, (2) diagnostics, (3) prognostics, and (4) user interfaces to

provide the operator with an integrated awareness about the system's health.

GHASM - autonomous control process

Knowledge is Power

Robust Test Stand Operations through Next-Gen Real-time Analysis of Operations Anomalies

PM: Harry Ryan |

Fiscal Year: 2015 |

Status: Complete |

The intent of this project was to develop a revolutionary rocket propulsion test operations

analysis environment that expanded the scope and depth of critical knowledge available for

operations performance definition, health management, and diagnostics. The project was going

to integrate existing, standalone system analysis models with a proprietary integrated system

health management platform from Model Software Corporation (MSC) which was designed to substantially

minimize the system development expense, maintenance costs and significantly expand the situational

awareness and real-time diagnostics potential. Unfortunately MSC, the commercial partner in this

project, was unable to integrate NASA's test program with its own proprietary software to develop

a response database in a simulated real-time environment.

Robust test stand project attempted to improve operations at the A-1 test stand